RMG's woes: long work hours

The garment sector's main challenge now is the long work hours that result from weak supply chain, poor infrastructure, insufficient utility services and high migration rates, a study finds.

Though the usual work duration for a day is eight hours, workers press on for 12 hours on an average to earn some extra pay through overtime, the study—conducted by Mohammad Hasan, executive director of Babylon Group—adds.

The top official of the leading garment exporter put the findings in his book titled “Readymade garments industries in Bangladesh: A study on social compliance”.

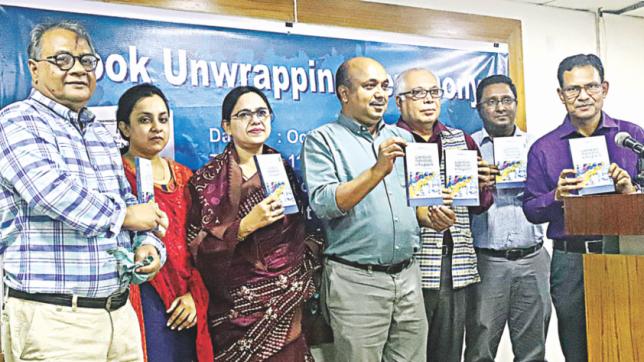

Hasan, who got a postgraduate doctoral degree on the garment industry, unveiled the book at the public administration department of Dhaka University yesterday. He conducted the study among 7,728 workers of four factories in Savar in March. It showed that Rangpur and Rajshahi divisions accounted for the two biggest sources of workers: 40 percent and 17 percent respectively.

On another note, he said the time served by a worker in a particular factory was very short: operators from grade 3 to 6 were retained on an average for 2.04 years.

Hasan also said the minimum wage gazette is not accepted by all as a complete guideline for determining the sector's wages, nor should it be believed that all were complying with it.

Past experience clearly demonstrated that the gazette itself created confusion and accelerated deprivation, he said.

Hasan in his book highlighted the rich history of the country's Muslin textile and how Bangladesh turned into the second largest supplier of garment items worldwide.

He said the garment sector matured in a journey of four decades.

The sector was primarily blessed with some visionary people like M Noorul Quader Khan, who set up the country's first export oriented Desh Garment factory at Kalurghat in Chattogram.

To make the factory viable, Khan partnered with Daewoo to get 130 people trained in Korea. Later, a majority of the trained hands turned into garment factory owners availing relevant quotas.

Hasan also mentioned the contribution of Lutfur Rahman Sarkar, a governor of Bangladesh Bank, who was involved in the introduction of back-to-back letters of credit for entrepreneurs who had a shortage of working capital then.

Another important player is Kihak Sung, owner of Korean company Youngone who came up with foreign investment from Korea and technological knowhow in the early years of the sector in pre-1980s to Bangladesh.

Hasan's PhD mentor, AKA Firoz, said this was the first such research and book in Bangladesh on the garment sector.

Hasan is not an academician and his educational background is on public administration, yet his book is very valuable for the country and for the garment sector, Firoz said.

Still the garment sector lacks skilled workforce, said Akter Hossain, a professor of the public administration department.

As a result, many foreign skilled workers take away billions of US dollars from Bangladesh as salaries and allowances, he said.