Videojet Announces the SureShot Module to Facilitate Continuous Packaging Line Production

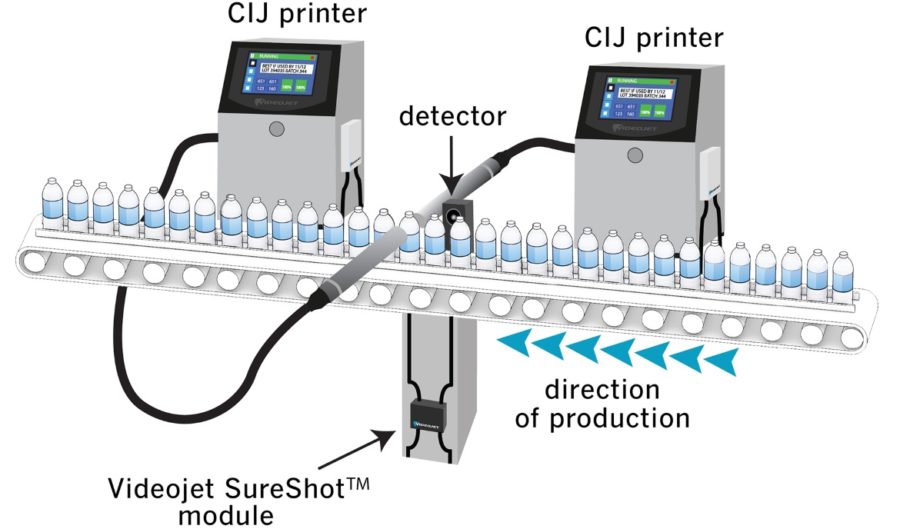

Videojet Technologies, a global leader in coding, marking and printing solutions, announces the launch of Videojet SureShot, an innovative module designed to work with pairs of Videojet continuous inkjet (CIJ) printers, helping to streamline production and maintenance.

With Videojet SureShot, two CIJ printers that are in print-ready mode can be configured to alternate printing on products as they move on a conveyor. If one printer is taken out of print-ready mode for maintenance, the second printer automatically assumes printing on all products until the first printer is put back into action. If the second printer is also taken out of print-ready mode, a signal can be sent to stop the production line.Read More : Essentra Packaging Invests in Digital Printing for Cartons with a Landa Nanographic Press Available for use with most Videojet CIJ printers, SureShot allows scheduled maintenance to be performed without stopping the production line. For example, when the Videojet 1880 auto-rinse feature is used to clean the printhead, a secondary printer can continue to print until the procedure is completed, without stopping the production line. Fewer operator interactions with the printers and a stable printhead placement help to eliminate operator errors to reduce cost from waste and rework.

“We know our customers need their production lines to run at high efficiency and maximum uptime,” said Mark Breunig, Product Manager for Videojet. “Customers using the SureShot module can help ensure that the coding process does not impede their production goals.”

Videojet CIJ printers are engineered for optimal performance in a variety of conditions. Operation is maximized through CleanFlow technology that helps prevent ink build-up in the printhead, keeping the printer clean and running longer, even in harsh environments. Fluids replenishment via a SmartCartridge fluid delivery system helps to virtually eliminate spills and ensure the correct fluids are being used. With simple user interfaces and networking options, Videojet printers are designed to deliver clean, consistent codes, time after time.

With Videojet SureShot, two CIJ printers that are in print-ready mode can be configured to alternate printing on products as they move on a conveyor. If one printer is taken out of print-ready mode for maintenance, the second printer automatically assumes printing on all products until the first printer is put back into action. If the second printer is also taken out of print-ready mode, a signal can be sent to stop the production line.

“We know our customers need their production lines to run at high efficiency and maximum uptime,” said Mark Breunig, Product Manager for Videojet. “Customers using the SureShot module can help ensure that the coding process does not impede their production goals.”

Videojet CIJ printers are engineered for optimal performance in a variety of conditions. Operation is maximized through CleanFlow technology that helps prevent ink build-up in the printhead, keeping the printer clean and running longer, even in harsh environments. Fluids replenishment via a SmartCartridge fluid delivery system helps to virtually eliminate spills and ensure the correct fluids are being used. With simple user interfaces and networking options, Videojet printers are designed to deliver clean, consistent codes, time after time.

Source: www.packagingstrategies.com

Useful Links: