Cheap rawhides have nothing to do with high prices of leather goods: experts

That very low prices of rawhides will be able to keep prices of leather goods such as for example footwear and bags from going abnormally saturated in the domestic markets isn't necessarily true, finds research of the Bangladesh Trade and Tariff Commission (BTTC).

Generally prices of leather goods such as for example footwear, belts and bags are anticipated to be suprisingly low since prices of rawhides, the key ingredient for making leather goods, has been lower in the country over many decades.

However, leather comprises significantly less than 5 % of the production cost of a set of leather shoes, according to a senior research officer of the BTTC.

Other costs have a tendency to be high such as for example those for labour, transportation, branding, administrative and managerial works and running establishments alongside that of bank interest levels and stock lots.

As a result, the low prices of rawhides aren't reflected in prices of leather goods in the domestic markets.

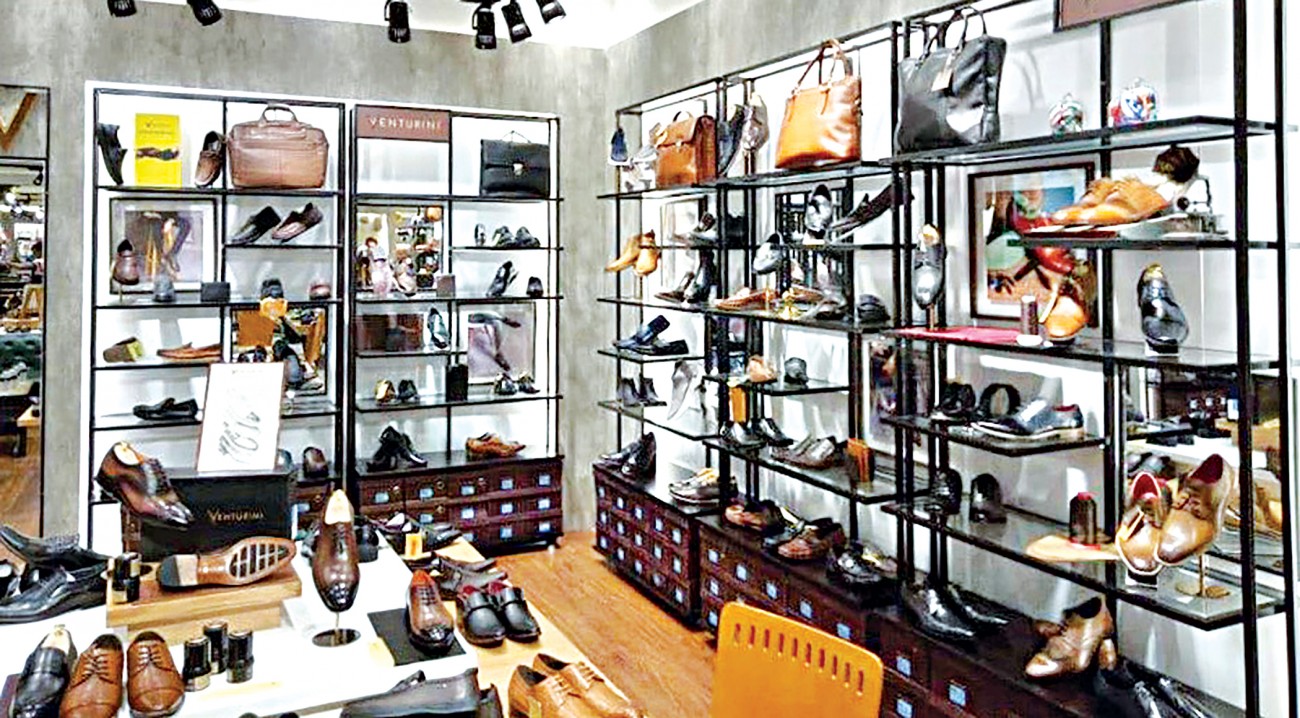

Moreover, local leather footwear and leather goods manufacturers have recently considered making high-end and semi high-end goods for customers as demand for all those increased with rising incomes in Bangladesh, the BTTC official said seeking anonymity.

As a result, the costs and comfort of leather goods increased in the country although the longevity of the shoes and bags decreased significantly.

For example, most leather footwear companies used wood to create soles, meaning the bottom part of shoes, which tended to effect a result of longevity. But nowadays, the soles are manufactured from natural rubber, which costs higher.

Usage of non-leather footwear such as for example sneakers, almost all of which are imported, in addition has increased in Bangladesh, the BTTC official also said.

Demand for synthetic or nylon thread-made non-leather footwear is higher among middle and upper middle income people in cities. A section of affluent and health conscious citizens use these things to go to their offices, as a fashion statement or just for outdoor activities such as for example running.

Even office-going executives use non-leather footwear items. A substantial number of folks use non-leather shoes as official shoes because they like everyday attires for likely to offices. These changes attended about mainly for changes in tastes in the world of fashion.

Due to this fact, leather shoes are being squeezed out from the markets, which includes also had a poor effect on their sales.

This has prompted leather goods manufacturers, especially people that have shoe segments, to create hefty profits from sales of less quantity of shoes to fewer customers.

Moreover, leather goods manufacturers say they sell goods in bulk quantities only on a small number of occasions around the year such as for example Eid-ul-Fitr, Pahela Baishakh, Eid-ul-Azha and Durga Puja.

For the rest of the year, they can not log sufficient sales despite having to continually spend money for running their businesses such as for example for operating showrooms and maintaining employees.

The BTTC blames an organised syndicate for prices of rawhides hovering at abnormally low rates in the neighborhood markets over the past two consecutive years.

Moreover, tanners incurred losses of around Tk 500 crore while relocating their factories from the city's Hazaribagh area to Savar Tannery Industrial Estate (STIE) in 2017.

They have been suffering from a cash crunch because of this, said the BTTC official who has been conducting research on the leather industries over the years.

The official's views were echoed by Abu Eusuf, a professor of economics in the Department of Development Studies of the University of Dhaka.

The cost of leather is quite minimal in the complete production and marketing cycle of leather shoes, said Eusuf.

However, bank interest rates and the price tag on availing finance, accessories, marketing, establishments, showrooms, labour and others are very high, leading to prices of leather shoes to go very high, he said.

A shoe manufacturer always raises the cost of a couple of shoes by Tk 1,200 to Tk 1,500 from you see, the production cost to survive. Because of this, the sales price of a set of shoes stays fixed between Tk 4,000 and Tk 4,500 in the local markets.

Eusuf also blames the existence of synthetic shoes for prices of leather shoes being high.

The costs of rawhides remained low for the past two years due to the fact tanners could not get into full production in the STIE and incurred significant losses while shifting from Hazaribagh to the STIE, he said.

The tanners are also suffering from too little financing from the banking sector, said Eusuf who has conducted research for long on the rawhide and leather industries in Bangladesh.

Many tanners and merchants have already turned bankrupt for failing to make good business from rawhide and leather products, the professor also said.

Bangladesh Competition Commission (BCC) is preparing to accumulate information from local markets to see whether any particular company, group or syndicate have already been cheating customers to create hefty profits from sale of rawhide and leather goods, said its chairperson, Md Mofizul Islam.

Primarily, if any manufacturer can produce even 10 pairs of shoes from a piece of rawhide and sells each pair for Tk 4,500, the full total value stands at Tk 45,000, he said.

If the production costs and other costs are fixed at Tk 3,000 per footwear, the profit is Tk 1,500 from some shoes in the domestic market.

However the price of a bit of rawhide now in Bangladesh is not even Tk 500, he said.

"We begins collecting information soon from the marketplace. If the BCC finds anybody accountable for abnormal price hikes of shoes and leather goods, we will serve notices to them."

"The BCC may also find out whether any syndicate or vested quarter is involved with turning prices of rawhides abnormally lower in the united states," Mofizul Islam also told The Daily Star over the phone.

The high cost of production and high bank interest rates are resulting in the abnormally high prices of leather shoes in the united states, said Mohiuddin Ahmed Mahin, president of the Bangladesh Finished Leather, Leather Goods and Footwear Exporters Association.

Manufacturers do raise prices by a supplementary Tk 1,200 to Tk 1,500 from the actual production cost of some shoes, which ultimately leads to store prices which range from Tk 4,000 and Tk 4,500, he said.

"Around 2.50 to 3 square feet of leather is required to make some shoes but another 100 types of items are also needed," Mahin said. Of these, only thread comes in the neighborhood markets and most of others are imported, he added.

Moreover, the average rawhide sourced from Dhaka is of 25 square feet while 20 square feet outside but the sizes shrink significantly after tanning in factories.

In summer the caliber of rawhides deteriorates a whole lot and the number of available leather is significantly reduced. As a result, leather prices rise, he said.

So by the end of your day, the manufacturers fix high prices of shoes due to high gas and electricity bills, salaries and other costs, added Mahin.

Of the cost incurred for making a leather shoe, 30 % is for leather and the rest of the 70 per cent for accessories, said Md Shaheen Ahmed, president of Bangladesh Tanners Association.

The accessories are pricier compared to the leather for which the prices of shoes are saturated in the local markets, he added.

High prices of shoes result form high costs of production, bank interest levels and recycleables like chemicals and salt, said Saiful Islam, president of the Leathergoods and Footwear Manufacturers and Exporters Association of Bangladesh.

Although the costs of rawhides are low in the local markets, that of tanned leather isn't. For example, a square foot of tanned leather was sold between $1.70 and $2.50 over the past two years despite a reduction in rawhide prices, he said.