Bike makers look for duty benefits for raw materials

Motorcycle makers have demanded duty rewards on component and natural material imports to be able to reduce the cost of production and develop the neighborhood two-wheeler industry.

Motorcycle Producers and Exporters Association of Bangladesh (MMEAB) and Bangladesh Honda Individual Ltd (BHL) separately placed this demand yesterday to the National Panel of Revenue (NBR) in the spending plan proposal for next fiscal, held in the first week of March.

In his spending budget proposal, Himihiko Katsuki, taking care of director and ceo of BHL, said there is no doubt that the local motorcycle markets has great potential to grow through assist from the country's large population and steady economical growth.

"We've already started locally making frames and swing hands good government's localisation insurance plan," Katsuki said.

Besides, as part of BHL's expense, the business has started a complete phase engine assembly brand.

"At our plant, we maintain the highest global standards collection by Honda to accelerate the industrialisation of Bangladesh and make motorcycles less expensive, he added.

From the research and development aspect, BHL has carefully studied the neighborhood customers to develop the Dream 110, Honda's first motorbike designed solely for Bangladesh at an affordable price of Tk 89,900.

This way, Honda is committed to providing the best quality products with realistic prices to contribute to society by spreading the joy and freedom of mobility.

The government decided to promote motorcycle production to a prioritised industry looking at its socio-economic importance together with its significance as a fairly easy and cost-effective mode of transportation.

BHL currently imports Completely-Knocked Down (CKD) kits for engine ingredients, which are segregated into more than 200 parts, 32 which are essential but should be imported separately.

"So we aren't obtaining the required duty rewards," BHL's proposal said.

Under these circumstances, the business is paying comparatively higher duties though it locally manufactures particular components, such as the chassis and swing arm, as directed by an NBR circular.

This makes BHL's finished product less competitive because of higher production costs.

"That is why we happen to be facing extra issues in localising the creation of varied parts, which are usually manufactured by the original engine maker.

"Besides, we cannot make these parts, such as the fuel tank and various plastic add-ons, since our means are tangled up in framework/chassis and swing arm making," it added.

To free up some of its own means, BHL signed a memorandum of understanding with Runner Automobiles Limited (RAL) in February 11 for the latter to create certain components.

In the MMEAB's proposal, the association explained the federal government did not increase the customs duty on motorcycle components in its cover fiscal 2020-21.

However, the NBR does withdraw the exemption of value added tax in local manufacturing.

MMEAB President Hafijur Rahman Khan said this decision is detrimental for the motorcycle industry since it would hinder the expansion of local vendors.

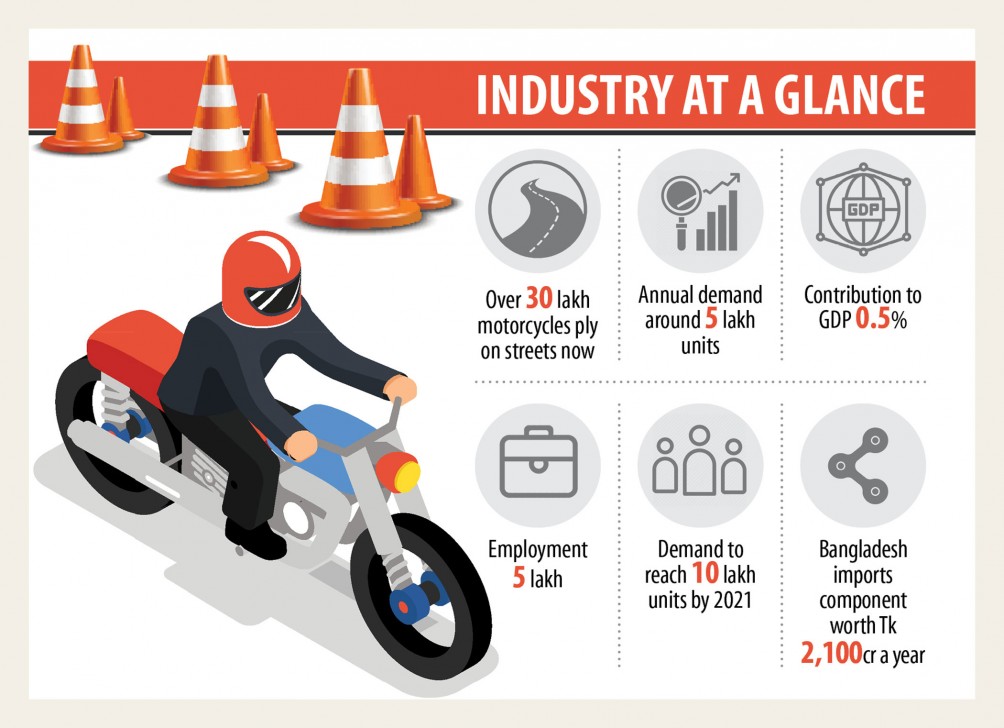

At the moment, over 30 lakh motorcycles are plying the streets in Bangladesh as the annual demand has already reached around 5 lakh units, according to data from the Bangladesh Street Transport Authority.

The 2018 policy was formulated by the government to attract foreign investment in this industry.

Desire to was to raise the sector's contribution to gross domestic product from the existing 0.5 per cent to 2.5 % by 2027 by expanding the industry's capacity.

The industry happens to be dominated by the assembly of imported components.

The federal government set a target to enable local manufacturers to produce around 5 lakh motorcycles annually by 2021 and 10 lakh by 2027.

After that, the policy likewise aimed to increase occupations found in the sector to 15 lakh from the existing five lakh.

"This light engineering sector with its supply of original spare parts is an extremely significant enabler for the local motorcycle sector," Khan said.

Once the insurance policy was formulated, Honda, Bajaj, Yamaha, Hero and TVS started developing motorcycles in Bangladesh, bringing together foreign and community investors.

Local manufacturers just like Runner, New Grameen and Roadmaster are also wanting to boost their technology and go for exports to Nepal, Bhutan and different countries.

In line with the MMEAB president, expenditure in the sector at the moment stands at about Tk 8,000 crore.

Insurance policy support from the government helped significantly to cut back the imports of motorcycle components, saving forex and enriching domestic reserves along the way.

But of program, locally assembled motorcycles right now dominate the marketplace, he said.

During the previous fiscal, motorcycle makers urged the government to keep exempting VAT on revenue of locally-made parts until 2027 to keep rates low.

However, the government didn't entertain their request.

Bangladesh needs to import elements worth Tk 2,100 crore annually to be able to focus on the demand for extra parts and components.

If the government gives insurance plan support to motorcycle makers, they would have the ability to develop local suppliers supplying these parts by creating original equipment manufacturers.

Besides, employment found in the sector would rise while numerous new entrepreneurs will be introduced aswell, Khan added.